Subassembly

This is a service we provide that truly sets MetPlas apart. The savings add up all the way from the ordering process to your manufacturing floor…Fewer purchase orders to one supplier, less inventory, reduced labor in your manufacturing process.

We have provided assemblies for medical devices, rail vehicles, electrical equipment, laboratory equipment and other applications where multiple components come together to complete a finished product. Some highlights of our assembly capabilities include:

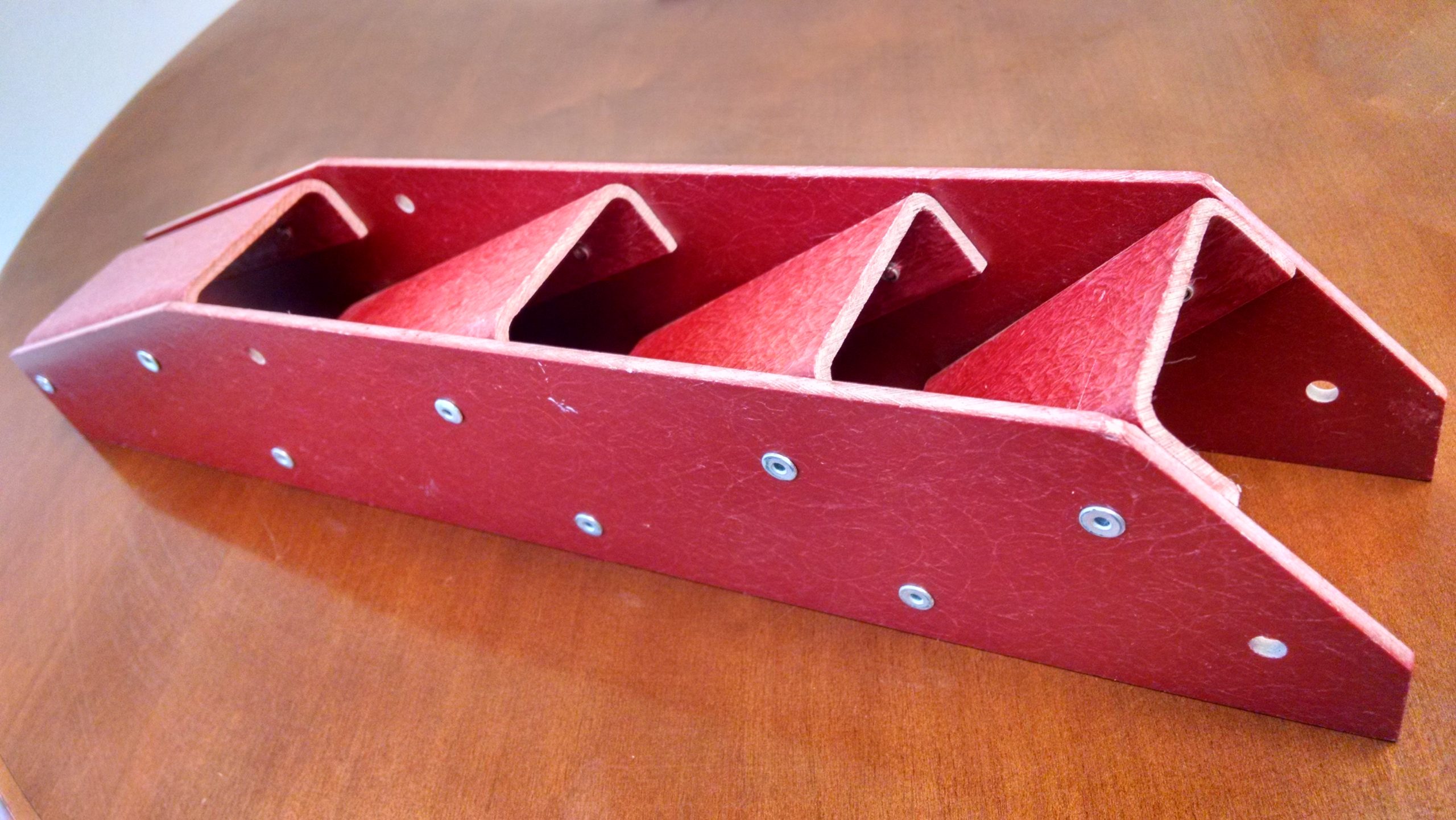

- Mechanical assembly

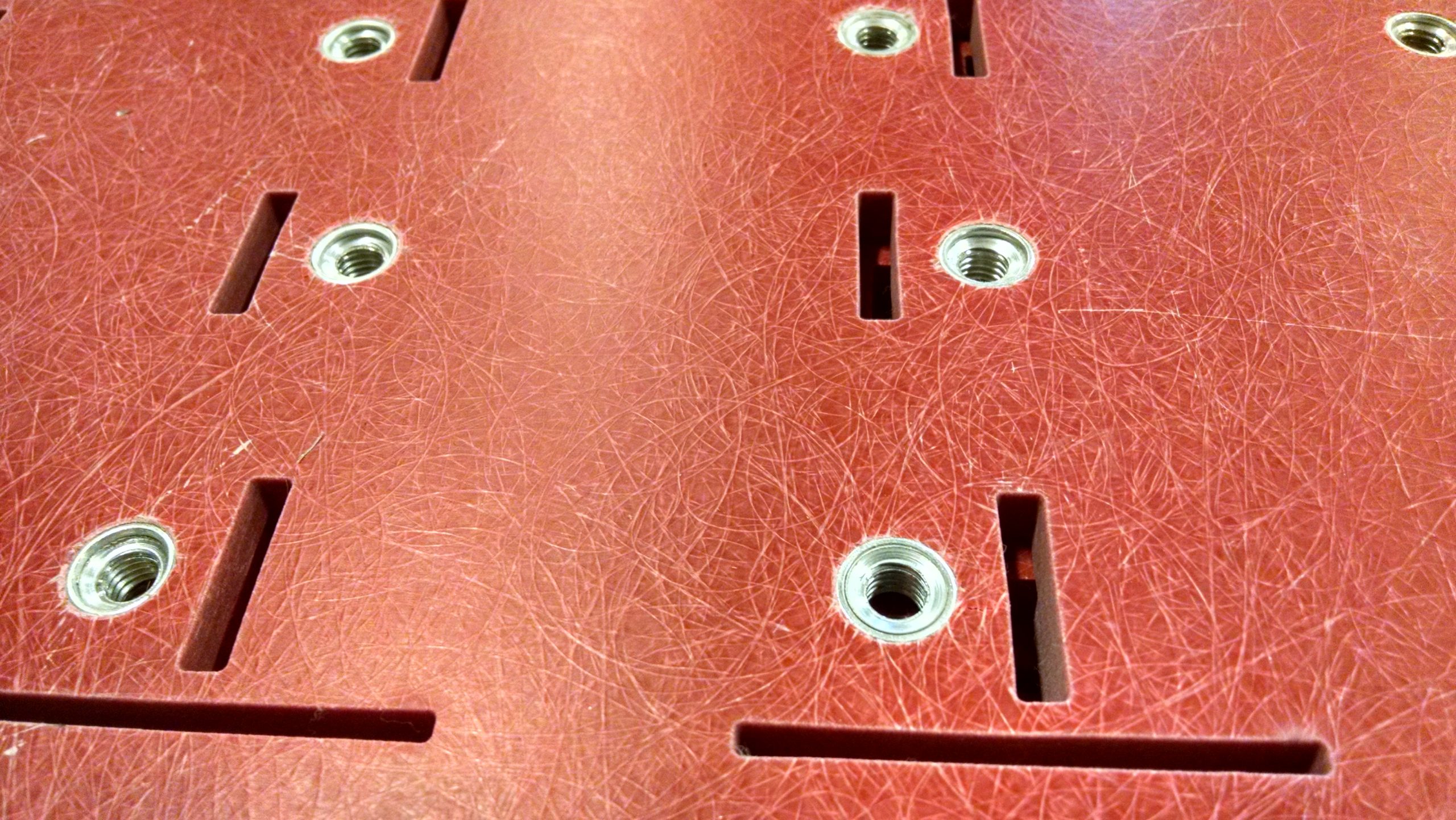

- Installation of a multitude of inserts for plastics and metals

- Assemblies involving plastics and metals

- ISO 9001 Quality built into every assembly

Subassembly Image Gallery

Engineering Tip:

Plastic and fiberglass materials are especially difficult to decide which style of insert is the most compatible with your material choice. With so many options available we’re happy to discuss with you what is available and what we’ve seen work best in our years of experience installing inserts into plastics.

You may also be interested in:

Precision Machining – Our diverse machining and fabrication capabilities are used to make the custom components that make up your assembly.

Waterjet Cutting – If your part is flat it may be best-suited for a waterjet instead of a CNC machine. We can quote it both ways for you.