Waterjet Cutting

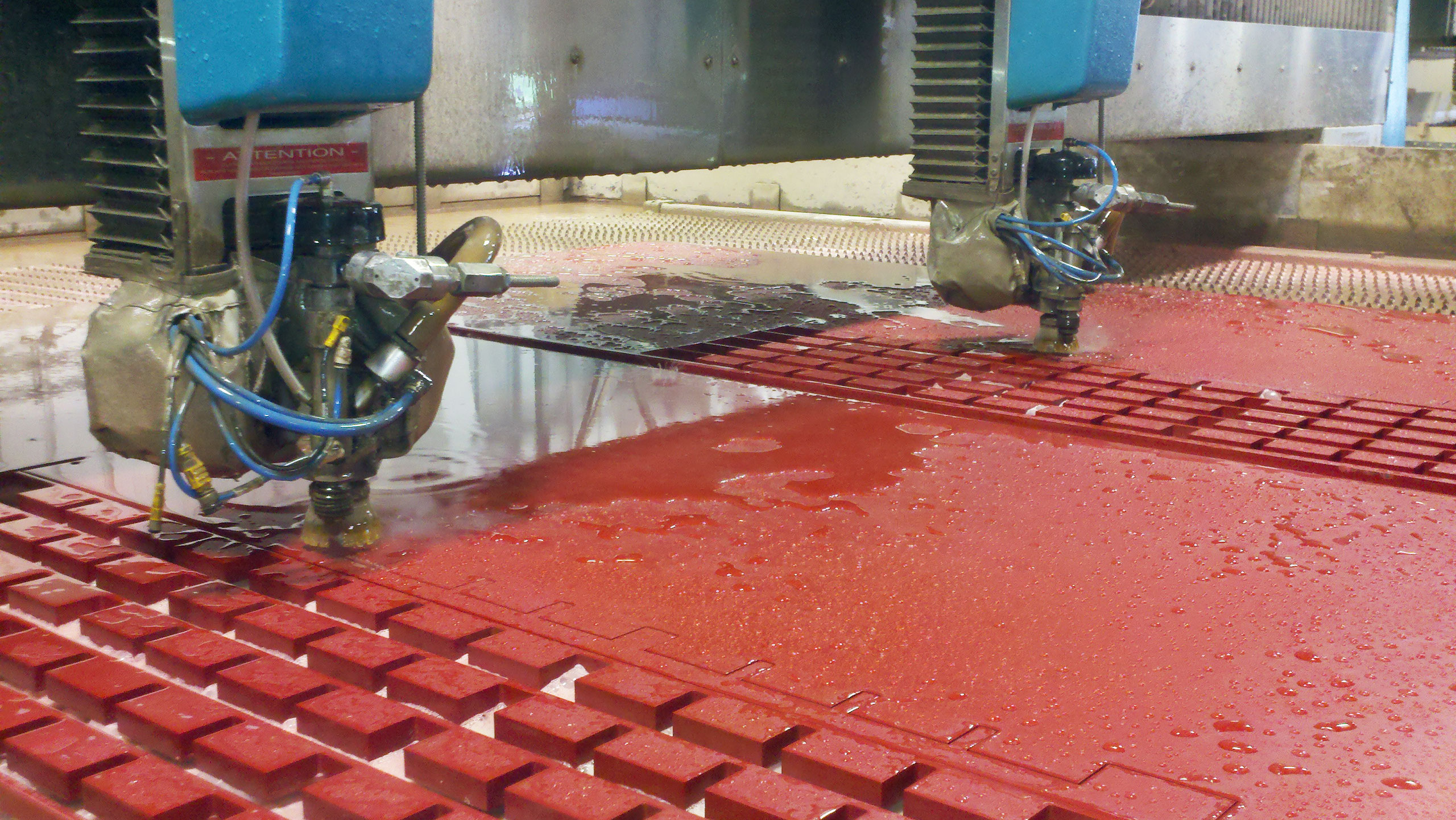

Our Flow waterjets are some of the best in the industry but it’s our operators that set MetPlas apart. We have over 25 years of waterjet cutting experience, providing low and production volume parts to a variety of industries. Waterjets offer the following advantages:

- Burr-free edge

- No heat-affected zones

- Minimal setup time

- Tighter tolerances with thicker materials

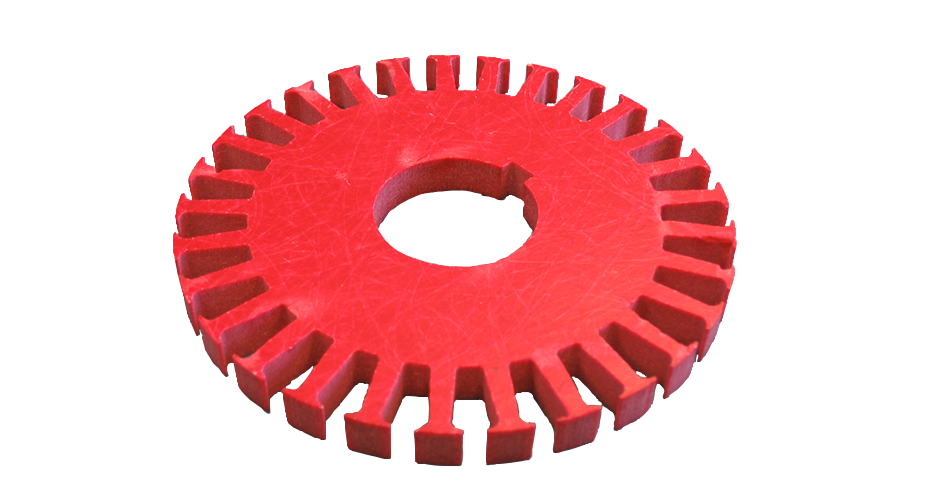

- Tight nesting of parts within sheets to minimize wasted material

- Broad range of material cutting capability including plastics and high-hard alloys

We provide:

- Max capacity 12ft x 13ft x 10”+ thick

- Dual-head hyperjet for efficient production quantities

- Dynamic cutting heads eliminate edge taper

- Typical tolerance +/- .010” depending on material and part configuration

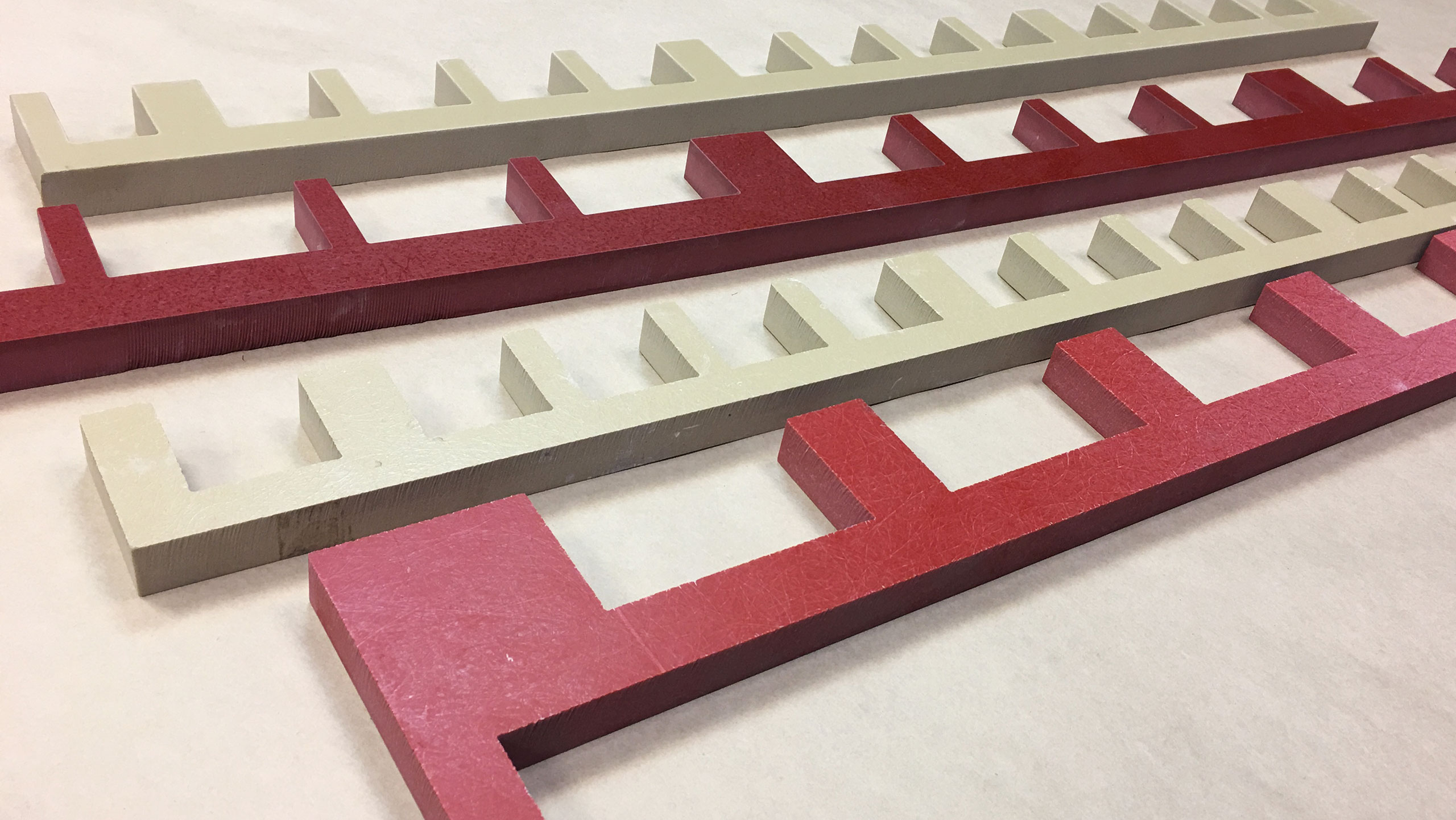

WaterJet Cutting Gallery

Engineering Tip

A couple of the biggest cost drivers in waterjet cutting are the tolerances and number of holes or cutouts. Tolerance drives cost because the tighter the tolerance ,the slower we have to cut. Each hole and cutout requires a piercing operation which takes additional time.

You May Also be Interested in

Precision Machining– Sometimes we first cut out the basic shape of the part on the waterjet to maximize sheet yield and then put it on one of our CNC mills to finish the part.

Subassembly– If your machined part is going into a larger assembly then it may be something we can assemble for you.